-40%

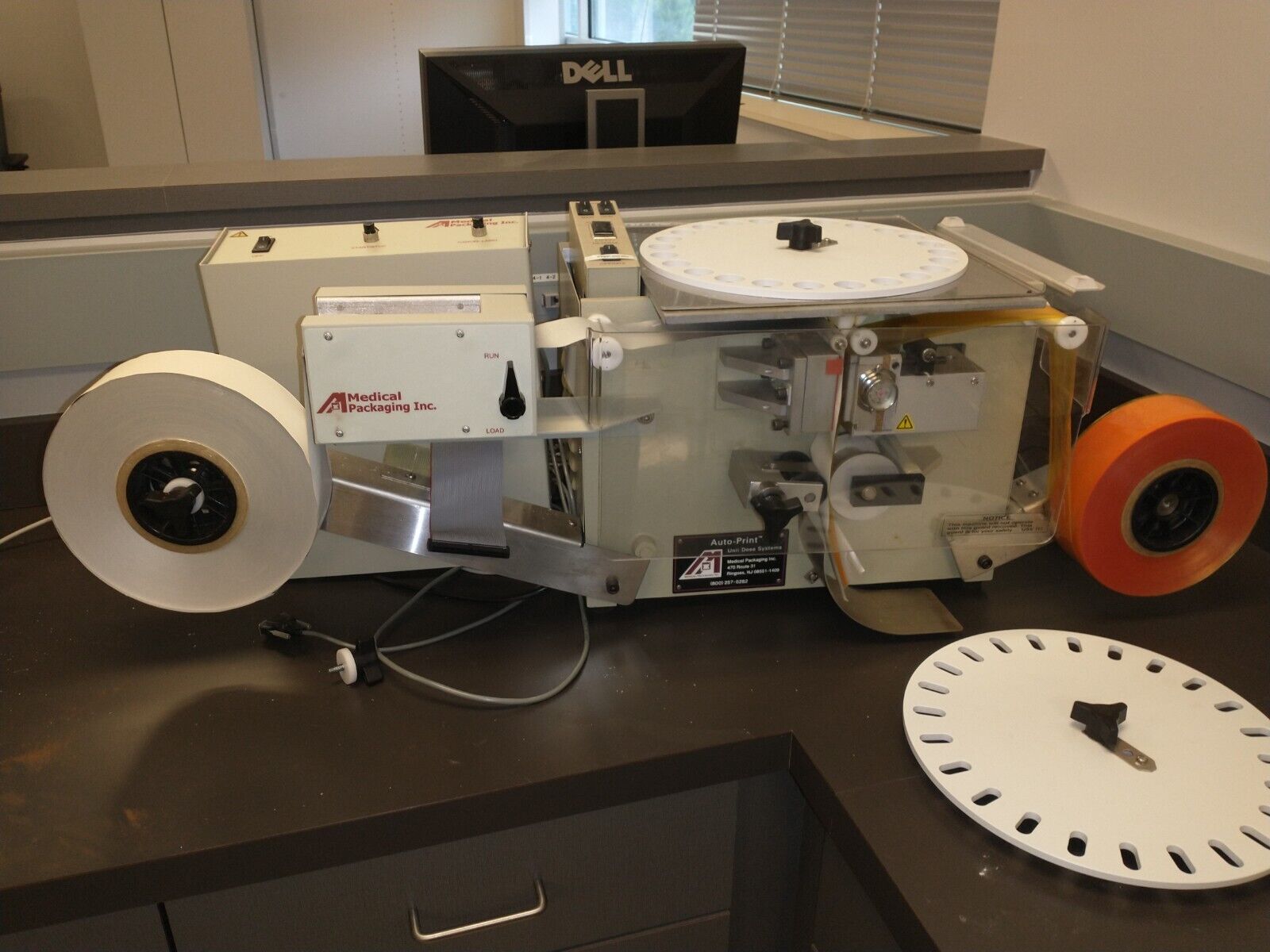

MEDICAL PACKAGING INC Pill Packaging Round table packaging, printer Works Great!

$ 844.8

- Description

- Size Guide

Description

This unit came out of a Pharmacist training class at a major university.Good working condition

Comes with a cables and connections.

The MPI Auto-Print Unit Dose Packaging System

The processes by which these materials are manufactured, and the products that are used to create the materials, are FDA registered for use in drug packaging and as such, meet the USP standards for Class A and Class B medication packaging. In accordance with the guidelines set forth by the U.S. Pharmacopeia, a one-year-beyond-use date (BUD) can be affixed to the repackaged product, or the remaining expiration date of the product, whichever is shorter. MPI has developed consumable materials that meet the Class B requirements set forth by the USP for moisture permeation and Class A requirements for light transmission.

The package sealant and adhesive layers conform to the FDA requirements for use in direct food contact providing for contact surfaces which are not reactive, additive, or absorptive.

Technical Specifications

Produces up to 60 packages per minute

Standard package size is 2″ x 1½”

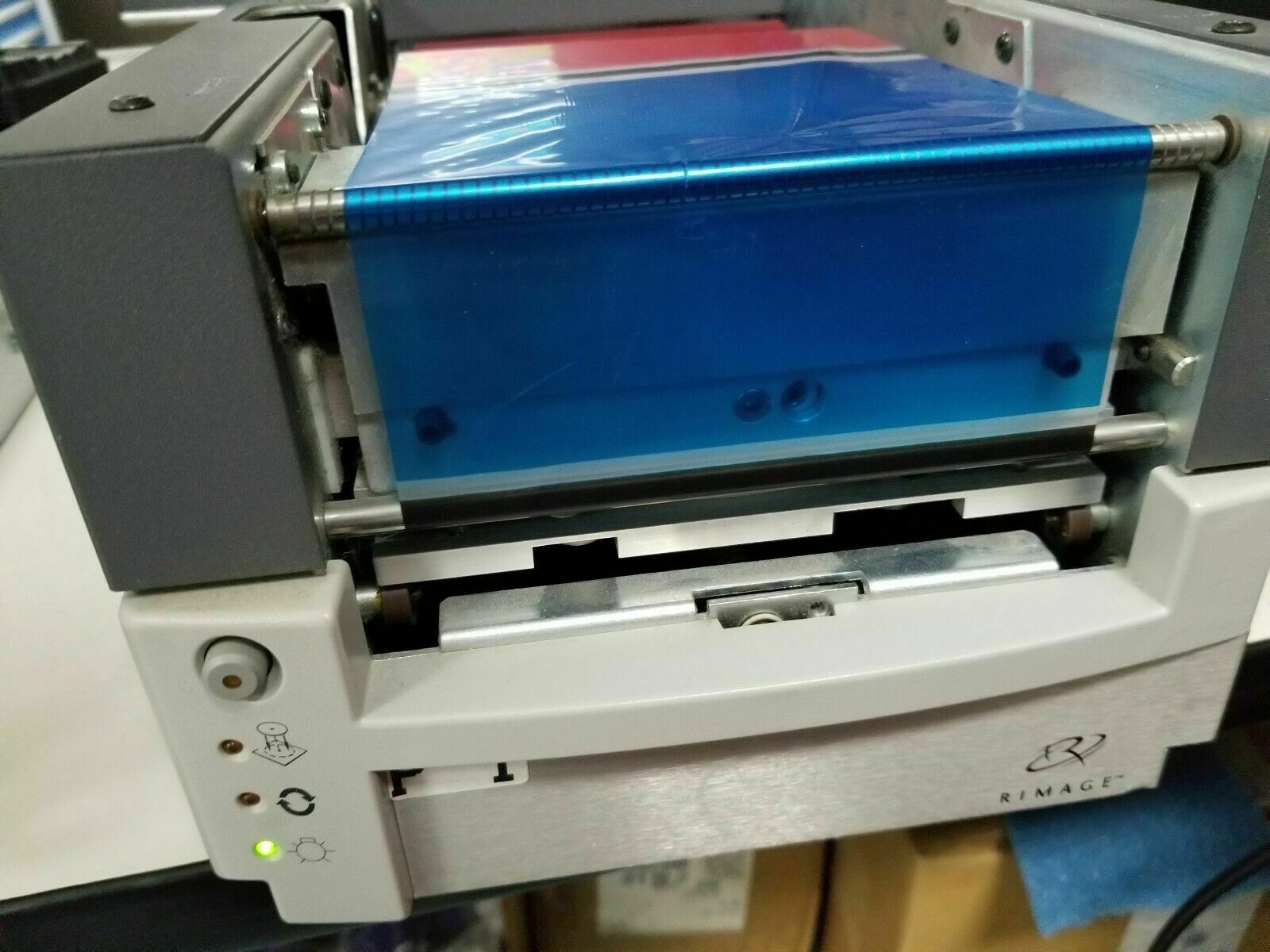

Model #9300E Printer: Ethernet port ready with 300 DPI resolution

Includes MPI’s exclusive Pak-EDGE™ Windows®-based software with access to First DataBank™ drug data, imprints, and images library

Size

: 36″ L x 15″ W x 14″ H

Weight

: 65 lbs.

Power

: 115 VAC 60 Hz, 320 VA or 230 VAC 50 Hz, 320 VA

Sealing Temp

: 200°F, no degradation to medication, no fumes

Safety

: CE, NRTL (MET) US, C. Includes safety reverse switch and clear protective guard with safety interlock. All moving parts are guarded. Circuit breakers on all circuits and a separate power supply for thermal printer

Hardware Requirements

: Computer with Windows

®

10 or higher operating system, 10 GB hard drive space, 8 GB RAM, available USB ports, desktop or network printer for reports, Internet access

Software Requirements

: Pak-EDGE™ UD Barcode Labeling Software (provided with packaging system) with optional access to First DataBank™ drug data, imprints, and images database

Material Requirements

: Requires the use of MPI-authorized disposable materials

Space Requirements

: Sturdy and level countertop, height between 28″ and 36″ for comfortable working conditions. Clearance above the counter should be 18″ to 24″. Minimum depth of 18″ with 4′ to 5′ minimum counter space in length. Packager connects to the computer via a 10′ USB cable that is supplied with the packager. The Auto-Print requires two (2) 120V outlets. The Oral Solid Feeder (OSF) requires one (1) additional 120V/230V outlet. Allow additional room and electrical outlets for your computer.

Barcodes Supported

: All linear and 2D barcodes are supported.

Chutes/Disks

: The Auto-Print ships standard with two (2) pill chutes—1″ Large and 5/8″ Small—and two (2) feed disks—Round/Tablet (1″) and Oblong/Capsule (1″)—to accommodate standard size tablets and capsules. Additional pill chutes and feed disks are available for purchase to accommodate non-standard size tablets and capsules.

Variable Length Option

: The optional variable length feature adds the capability to change the package length as needed. Pre-loaded software templates are available for each standard package size and software label preview accurately represents package size. Standard available choices for variable length packages include: 1″, 1 1/8″, 1 1/4″, 1 3/8″, 1 1/2″, 1 7/8″, 2 1/4″.

Barcode Verifier Option

: The optional barcode verifier automatically scans each package as a final check after the packaging of the unit dose container is completed to assure that the barcode can be accurately scanned at the bedside. If an unreadable barcode is detected the system will pause to allow the user to retry or remove the package from production.

Medication Packaging

MPI has developed three distinct MPI-certified consumable materials for exclusive use in MPI’s Auto-Print packaging system to create the unit dose package,

Auto-Print SUPERTHERM

®

thermal paper, which can be combined with

Auto-Print SUPERCEL

®

film or

Auto-Print SUPERFOIL

®

.

Direct thermal printing technology, proprietary to MPI’s Auto-Print packaging system, is utilized to print barcode and medication information directly on the Auto-Print SUPERTHERM

®

side of the unit dose package to assist in error prevention and compliance for repackaging of medication. Auto-Print SUPERTHERM

®

thermal paper is comprised of smudge-free and fade-resistant materials that allow for easy scanning of the barcode and medication information contained on the unit dose package.

The Auto-Print SUPERCEL

®

side of the unit dose package allows for clear visibility of the packaged medication, and six different colors of film are available to allow for identification of controlled medications or for use in color coding medications by expiration dates. If medication is packaged using Auto-Print SUPERFOIL

®

, which is typically used for medications with short shelf lives or for products that are sensitive to moisture and light, the packaged medication will not be visible

The combination of MPI-certified consumable materials to create a unit dose package assures no degradation to the contents or the package seal integrity. The built-in low sealing temperature and built-in printer provides assurance to the packaging pharmacy that all medication will be adequately protected from external environment effects such as light or moisture and a that a clear, legible, fully sealed unit dose packaging is produced every time.

Medication Barcoding and Labeling

The unit dose packages created by MPI’s packaging systems and Pak-EDGE™ UD Barcode Labeling Software are capable of accommodating all linear, 2D, and GS1 barcodes. The software used to generate these barcodes was developed exclusively by MPI and is continually upgraded to include the latest advances in barcode technology for pharmaceutical packaging. The software allows for unlimited number of barcode configurations, which typically include product NDC code, local expiration date, and date packaged. In the event of a product recall, MPI’s Pak-EDGE™ software can easily trace the packaged product so the pharmacist can take immediate corrective action to remove the product from inventory.

Benefits of Implementation

The combination of packaging oral solid medication with MPI’s Auto-Print packaging system and our exclusive MPI-certified consumable materials, coupled with the advanced barcoding capabilities and configurations available in MPI’s Pak-EDGE™ software, provide our customers with the continued confidence that each unit dose package will be produced in adherence to industry guidelines for light, moisture, and sealing. A safe, tamper-proof unit dose package containing detailed medication and barcode information will be delivered to the bedside each and every time, ensuring patient safety.

Shipping:

We sell AS-IS

Buyer Pays for ALL Shipping Cost's

The buyer pays for all shipping costs. Item to be sent via FedEx because they are more gentle with their handling.

Returns We sell quality used equipment. We sell as-is. With that being said, if you do have any problem’s please contact us so we can see what we can do. We want happy customers!!

Contact Us We take joy in helping you get the EQUIPMENT you want at the price you need. It is your responsibility to resolve any questions before your purchase.

Please don't hesitate to contact us with any questions or concerns. You can contact us via eBay message.

We work hard to include a lot of pictures of each item. We do our best to describe items and their conditions.

Please see item photos for all the details.

Buyer Pays ALL shipping costs

Shipping: FEDEX If you do purchase the item please send me your name address and phone number all are required for the bill of lading. I will send you a tracking number after shipping and update the shipping on the auction.

Sales are AS-IS

Disclaimer

The purchaser agrees that the seller is not responsible for any injuries or damages associated in way associated with this equipment. The purchaser by bidding on or making an offer on this equipment indicates their acknowledgement of this agreement to the terms of this disclaimer. Terms of Sale The purchaser agrees to indemnify and hold harmless seller, sellers officers, directors, shareholders, employees against any and all liabilities, obligations, claims, demands, cost and expenses of every kind of nature, including attorney’s and litigation expenses, arising from or related to equipment, including without the manufacturer, selections, purchasers, deliverer, possession, use, operation or return of the equipment or from any breach or default on the part of the seller in the performance of any agreement or seller to be performed pursuant to the terms of this agreement.